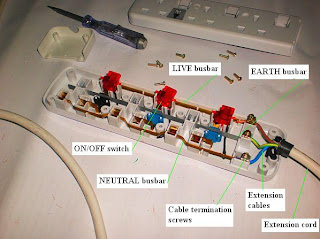

Picture 1 – Temporary electrical panel

===== RELATED ARTICLES: Temporary electrical installation pictures | Temporary electrical installation pictures | Temporary Electrical Earthing Pictures | Temporary electrical panel and cords pictures |

===========

I got involved with this new building project since a few weeks ago.

After reporting to work at the construction site, I spent the first few days attending a few meetings and on the fourth day I took my first round of general inspection around the building under construction.

I went out alone on that first inspection, bringing with me my old and cheap Canon digital camera. It was really a cheap camera and that is probably the reason the picture quality here are not so good.

My previous digital camera was much better but it got stolen when my car was broken into.

First things first

The first thing that I look for when starting on a new project site is always the temporary electricity supply equipment and their associated temporary cabling and wiring works.

There can be hundreds of workers are involved during peak period of activities in a building job of a few million dollars.

With a bad temporary supply installation and with most workers being generally ignorant of the dangers of temporary electricity, the risk of fatal electrical accidents is always high.

I did my round and took a few pictures of temporary electrical panels being used, the temporary supply cabling, wiring, and extension cords that were taking supply from temporary panels.

I selected a few of the picture shots that I took and sent it to the Main Contractor’s Project Manager together with the following Site Memo.

You can see a few of the pictures of the temporary electricity supply DB and their cabling works toward the end of this post.

SITE MEMO:

Dear Sir,

Re: Temporary electricity supply: Electric shock hazards

As I have explained on Saturday last week, please find attached photographs of the temporary electrical cabling.

I believe the photos are self-explanatory. However, I wish to highlight the following points:

Many extension cords do not have the grounding cable.

The extension cords are laid on the floor along main work traffic. Cables can be damaged leading to exposures of LIVE cables. A few have already been damaged and improperly patched up.

Observe that the area is a very wet area. The risks of electrocution here is very high.

I suggest the following action be taken IMMEDIATELY:

If possible, the temporary DB is relocated to a more suitable and DRY area.

Enforce the rules that all subcontractors run their extension cords at high level along walls or columns.

Enforce the rules that all extension cords have a working grounding conductor.

It is my opinion that the present situation is VERY DANGEROUS and a fatal electric shock accident can happen any time.

Regards,

Lee Wan Seng

Resident Electrical Engineer

Picture 2 – Temporary electrical cabinet

Picture 2 above shows the overall view of the temporary electrical cabinet where the temporary electric panel is located.

I know that many electrical readers are surprised by the way I accept these equipments and installations.

The temporary panel in the pictures is not what I would use if I am in charge.

Here I was not in charge. I was the resident engineer representing the professional electrical consultant in a design-and-build contract.

In this type of contract, the main contractor is the boss and the paymaster.

And this project was in a “third world country".

We in the construction and engineering consultant industry cannot turn the standard of our construction practices overnight, especially not in the design-and-build or turnkey types of contracts.

What we can do is to set out priorities in an order that can still be implemented on the ground within a particular contract scenario.

In this case, it was an issue of safety of human lives.

Even in this matter of life and death of many human lives, priorities must be set properly so that it can be implemented.

I could have rejected the whole temporary electrical DB and the temporary cabling in the picture.

In many situations, I have done so.

However, in real life situations, political factors are always present and everywhere, especially where there is a lot of money involved. That is the nature of life that I know.

To say it simply, if I rejected the makeshift temporary electrical DB, I would have been kicked out of the project in a matter of a few weeks and the main contractor would have easily found a replacement that would bend to their wills.

Of course I could easily find myself another job, even with much better paychecks and benefits if I want to.

However, nothing good would come out as far as the electrical safety at this construction site is concerned. It may even get worse.

That is why I sent out the above Site Memo.

If the Main Contractor take action as I advised (which they did immediately after receiving the memo) in the above Site Memo, then I would have made a strong improvement. That was a good first step.

The point here is that handling construction issues on the ground has as much to do with diplomacy and PR works as with technical issues.

One has to properly balance a number of top priority matters in order to get things improved enough.

That is a measure of effectiveness of the site supervision team in the real construction world.

Going back to the reason I made this blog, its objective is mainly to share pictures. With this method, I share my experience with the readers. Good experience, and the bad ones.

You will find lots of pictures showing good electrical installations here. You will also find tons of bad installations. I am not recommending anything by showing all these pictures, unless I specifically say so.

As long as readers find some uses from the pictures, then I would have accomplished my purpose by sharing the pictures that I have in this blog.

Enough said. Now let’s get back to the pictures.

Picture 3 – A view of the wet area around the electrical panel

This picture shows one situation was with a wet area around the temporary panel and unsuitable extension cords laying around on the building's ground floor.

From the point of view of safety practices and regulations, I think this real life example has broken about all the relevant codes in the book.

Picture 4 – Damaged extension cord

This shows a closer view of the extension cords laying on the work floor. They have no armor and could be easily be damaged.

A few have been already damaged and improperly patched up.

Picture 5 – Closer view of the repaired extension cables

Picture 6 – One of the portable electric tools

Picture 7 – Extension cords on the floor

Picture 8 – An example of electrical plug without earthing connection

I wish to emphasize a little bit here.

Why do you think the workers did not connect the green earth cable to the plug?

The extension cord already has 3 cables one of which was meant for grounding.

So why such a reluctance to do it?

The reason is almost the same most of the time. The ELCB on the electrical panel may trip if the green earthing cable is connected.

Portable electrical tools used at construction sites are mostly motorized tools (e.g. Drills, grinders, electric hammers, etc).

These tools always have an electric motor underneath the casing.

An electric motor always has a coil that transforms the electrical energy into the mechanical energy that do the work.

That is where the problem comes from.

Motor coils have a tendency to leak electrical voltage. Other moving parts behave similarly also.

The leaked electric voltage (Note: an electric voltage is an electrical pressure much like a water pressure inside a water pipe) would turn into a leakage current if the electric tool is properly earthed or grounded.

The flow of the leakage current would be detected by the ELCB (earth leakage circuit breaker) unit on the electrical panel and the ELCB would trip.

If the grounding conductor is not connected as shown in Picture 8, then the ELCB would not trip. So the worker using the portable electric tool could keep on working.

In another word, frequent trippings of the ELCB is a nuisance to the workers.

That is why they disconnect the green grounding conductor of the extension cord.

But then, without the grounding cable, the worker has zero protection against the risk of electric shock.

By that, I really mean absolutely NO PROTECTION AT ALL AGAINST ELECTRIC SHOCKS.

Picture 9 – Grounding of the temporary supply through the steel wire armor of the multi-core armored distribution cable

That is all I have for today. See you again in the next post.

Copyright http://electricalinstallationwiringpicture.blogspot.com Temporary electrical cabling